|

Turntables :

Turntables :

|

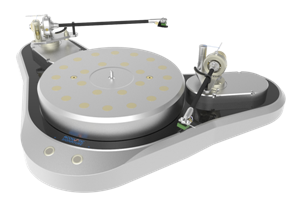

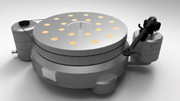

| NOVUM

| | | | | | |

|

INVICTUS -Best turntable

of the World

The Absolute Sound review:

http://www.theabsolutesound.com/articles/acoustic-signature-invictus-turntable-and-ta-5000-tonearm/

It is a singular experience to acquire an Invictus. Visionary art of

engineering meets progressive technology. Only the finest materials are used

in crafting it by hand. Invictus captivates users with a unique combination

of opulence, finesse, dynamic and quality.

A product with a personal touch. Discover something that is so unbelievable

at first glance: exceptional, rare, and truly individual. The Invictus is

your turntable.

The Invictus turntable has been in development for three years. It is the

result of intensive research and development by the manufacturers at

Acoustic Signature.

This incomparable

turntable has been assembled with a total of 479 individual,

hand-constructed parts. Up to four tone arms can be added in its

construction; the Invictus can be fitted with approximately every tone arm

thereby enabling a never before existent flexibility and at the same time

fulfilling the highest demands in musicality, rendition and aesthetics.

The base for the Invictus consists of an elaborately shaped lower section

optimized in terms of stiffness and low vibration according to the latest

knowledge in mechanics and application of finite element methods. A

perfectly shaped cover panel is placed over this with the actual Invictus

chassis resting on top of it.

The Turntable

itself is a three dimensional work of art that is capable of perfectly

supporting up to four tone arms simultaneously. Soft contours, sloping and

round surfaces are arranged here in a never before existent artistic

synthesis. Even so, the shape is successful for the function and is not an

end in itself.

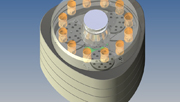

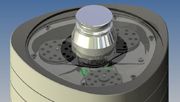

The 3-tiered aluminum and brass sandwich platter is likewise completely new.

It is manufactured to fit precisely in combination with a high damping work.

With their vibration absorption, the 54 silencer inserts provide for the

last grain of fine tuning – the result: a perfect platter. High damping with

high rotation energy. Soundwise, it is very progressive.

Our Tidorfolon bearing allows anyone with an eye for the extraordinary to

instantly recognize how this hand-tuned slide bearing has been perfectly

formed to guide the platter with approximately no clearance and likewise no

friction or sound. Our Tidorfolon bearing is valued and admired by fans and

experts all over the world for its precision and its legendary reliability.

It is always manufactured with great love for detail and precision in

accordance with the best fine mechanical tradition.

Drive System

The drive system is a very important component for a superior turntable. We

have started completely afresh here. The development was influenced by our

20 years of experience. The result is a silencer platter positioned above a

cone-shaped sub-platter propelled by a 6-motor drive system. The 6 motors

create enormous power for speedy running of the platter. The round assembly

surrounding the bearing prevents any pull so that it can be perfectly

centered.

We have performed very extensive developmental work for the “silent run”

technology in the digital motor controller. In the end, the result

compensated for all the hard work. Digital electronics constantly measure

the motors and adjust all motors for minimal vibration and the greatest

smooth running. Fully automatic and always exact. The result is a drive

motor system which you can touch without sensing if the motor is running or

not. Satisfactory enough to find its use in Invictus.

The result

The sum of new developments in connection with 20 years of experience in

turntable construction has produced a turntable in Invictus which we

consider a statement in turntable construction. The Invictus is worthy of

comparison to considerably more expensive products. Every single one of my

15 co-workers has brought their best to Invictus.

We had a lot of fun and amazing experiences in listening during our

developmental phase, and with personalized installation we would like to

ensure that your Invictus plays perfectly in your own rooms.

Sincerely,

Gunther Frohnhöfer

President Acoustic-Signature

Technical data

| Construction

details |

Aluminum, brass Sandwich |

| Speed change |

33 and

45 rpm, 78 as option |

| Motor drive |

6

motor drive DSP controller |

| Bearing |

TIDORFOLON Bearing |

| Platter |

Sandwich Silencer platter 345 mm |

| Weight |

Turntable 143 kg

Stand 168 kg

311 kg total |

| Dimensions (W/D/H

in mm) |

approx. 800 x 730

x 1210 with stand

approx. 800 x 730 x 350 turntable only |

| Color |

Aluminum |

|

Manufacturers guarantee

|

10 Years |

Read about the Ascona. Jonathan Valin Executive Editor of Absolute Sounds

writes about his Experience with the Ascona.

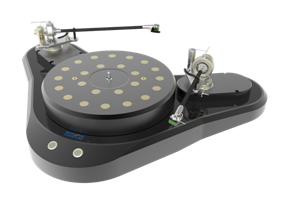

Welcome to the superb Ascona.

We set out to design a new milestone in turntable performance, an ‘ultimate’

high mass turntable, but still elegant and stylish. The Ascona has been

designed using our considerable in-house design knowledge and development

expertise built up over 15 years. The Ascona story starts with the platter

on which the record sits – because we know that the perfect turntable

requires a resonance free platter rotating perfectly, with great stability.

A very high mass platter is the answer, but needs designing carefully to

achieve the desired result, high mass on its own is not enough. Then there

is the motor to perfectly rotate the platter and the ‘arm board’ to

perfectly hold the arm – all needed radical re-thinking to achieve our goal

– the best sounding turntable we have ever produced, the best turntable ever

perhaps? Here are the technical features that make the Ascona so good:

• The record platter (Silencer-Platter3) design brief was clear: Elimination

of vibration due to impacting airborne vibration and elimination of bearing

noise - to remove resonance at all frequencies, especially in the range

400-6000Hz; and to increase of the rotating mass of the platter to aid

stability.

This desired performance brief has been achieved in the following way: A

50mm thick solid aluminium turntable platter is made from a very soft alloy

to optimize its periodic resonance and a resonance-reducing material is also

applied to the bottom face. Solid brass ‘Silencer’ inserts are used to

eliminate resonance. Ascona employs 30 small Silencer’s on the very outer

diameter of the platter; we needed to increase the platter diameter to

nearly 350mm to achieve this. A further 24 larger Silencers are used within

the body of the platter. The manufacturing process for the precision of the

holes to accept the silencers was once more refined. The holes are drilled

and “line-bored” with a clearance of less than 0.01mm to achieve a perfect

fit. The Silencers become an integral part of the turntable - highly

absorbing of all vibration energy, the platter remains inert and resonance

free. To ensure perfect platter balance, the holes are absolutely true about

the centre of the turntable.

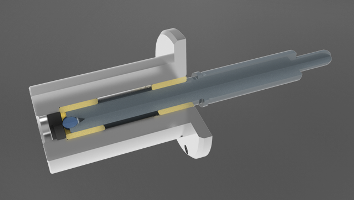

•The platter bearing is the heart of every turntable. Through fundamental

research and development, we have invented a bearing with the ideal

performance characteristics of exact fit, extremely low noise, very low

friction and long term stability. The platter bearing component is

manufactured from special hardened and polished steel, with an extremely

hard tungsten carbide ball at its base. The bearing housing uses perfectly

matched and ‘aged’ sinter bronze inserts which are self-lubricating; and

therefore maintenance free. At the base of the bearing, we use our specially

developed ‘high-tech’ material TIDORFOLON.

•The bearing chassis is milled out from a 70mm thick block of aluminium and

forms part of the integrated turntable ground-plate. Combined with the new

platter the Ascona has a weight of 80kg.

We grind the surfaces by hand, a lengthy but essential process to achieve

visual perfection.

•The external platter drive motor has 3 motors built into one housing. They

drive a subplatter on which the Flywheel is placed. So we have much more

power and stability than normal. Also the motor is run by its own electronic

controller (AlphaDIG), a design we developed for the Ascona, where fully

digital output stages and quartz locked technology, produce a perfect sine

wave at 24VAC to run the motor, resulting in a perfectly steady and constant

platter rotation. It is totally impervious to the negative effects of mains

voltage fluctuations, and household appliances that produce ‘noisy’ mains

that can have a very great detrimental effect on AC motors, and therefore

the turntable performance and the sound you hear.

•The tone arm mounting plates are the most rigid versions we ever designed.

They are adjustable to suit tone arms with lengths from 9 to 12 inches. The

mounting of any desired tone arm make is possible, and two tone arm mounting

plates can be fitted on the Ascona.

• Three adjustable feet for simple macro and micro adjustments to level the

turntable.

As you can see, we have done everything to develop a potentially perfect

product. The high mass, low resonance platter (with its inertia) is an

integral part of the turntable concept. Very low bearing friction and noise

and perfect motor drive control guarantee perfect synchronization and the

best sound. Highest precision manufacturing in Germany guarantees

reliability of this turntable. To make sure that every ASCONA is exactly the

same we produce nearly every part on high precision computer controlled

machines in-house.

Technical Data:

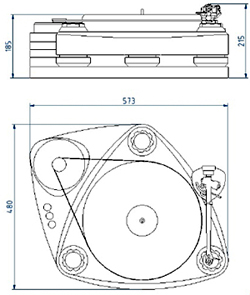

Total weight ca. 78 kg

Dimension: BxW 550mmx470mm

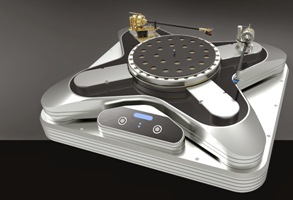

The NOVUM is a fully new

design...

IA fully new design

The NOVUM is a fully new design. A lot of new ideas never been done before

here at our factory. We left no stone unturned to create a stunning looking

table with enormous sound quality.

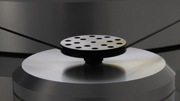

NOVUM is manufactured with our new revolutionary ‘24 Silencer Platter’

design, one of the most significant improvements in our turntable designs.

He is driven by 3 integrated invisible motors driving a heavy sub platter.

The NOVUM is designed and built for exceptional music reproduction,

outperforming turntables costing much more. The fully digital motor control

is situated in an external housing to generate perfect signals for the

motor´s and to avoid any influence to the cartridge.

The turntable base has been designed for optimum stability; the large

footprint of the table NOVUM is engineered to provide exceptional sound, but

its form is also attractively contemporary.

The Design

More ways to amaze. The new NOVUM is a consequent developed new design. It's

all combined with the award-winning performance, elegance, convenience and

comfort that have made the mass turntable Series so successful. Get ready to

experience of the NOVUM Series - now perfectly suited to your own unique

style. Perfect surface quality combined with the latest technology and

flexibility.

The NOVUM includes the 24 Silencer Platter and the latest version of the

digital motor electronic elegantly placed beside the Chassis. The tone arm

mounting plates are adjustable. The mounting of any desired tone arm is

possible, with a maximum of 2 tone arm mounting plates on one turntable.

Three adjustable feet for simple macro and micro adjustments to level the

turntable.

Drive System

At the new NOVUM we combine a massive Aluminum plinth of 70mm with a 50mm

massive Aluminum platter. This is a perfect fit for the Tidorfolon bearing

holding the platter and the exchangeable arm boards.

A new fully digital motor Electronic provides perfect speed stability and

easy operation is integrated into a external housing.

The carefully made Aluminum platter with his 24 Silencers is another part

which makes the sound of a NOVUM so outstanding for his price class.

The Platter

A 50mm solid turntable platter made of aluminum with 24 Silencer inserts.

The platter is made of a very soft alloy to optimize its periodic resonance,

and is coated on the rear side with resonance-reducing material. For the

Silencer- Platter the development target was clearly defined: Elimination of

vibration due to impacting airborne sound. Elimination of bearing noise,

increase of the gyrating mass. Serious elimination of all frequencies,

especially in the range 400-6000Hz. This was achieved by drilling 24 holes

into the turntable. The manufacturing process for the precision of these

holes was once more refined. The holes are drilled and afterwards separately

“line-bored”.

This allows a clearance of less than 1/100mm. Perfect conditions for the

force-fitting of the 24 silencer modules. The “silencers" are now an

integral part of the turntable - but highly absorbing. Existing vibration

energy is quickly reduced and the Platter is immediately steadied.

To avoid unbalances through the additional holes these are manufactured in

the same setting as the outer contour. In this way the holes are absolutely

true to the centre of the turntable. As you can see, we have done everything

to develop a potentially perfect product. This new platter is placed on a

sub-platter which is connected with the motor belt.

The Motor

We at Acoustic Signature believe that a motor system for a turntable should

have enough energy to speed up the platter but not influence him during

rotation. We reach that aim by using a European made Synchronous motor with

our own State of the Art motor control. The internal 3 drive motors of the

turntable are supplied by their own electronic controller. It is a brand new

design where fully digital output stages and quartz locked technology is

used.

It is impervious to the negative effects of mains voltage fluctuations and

household appliances that produce ‘noisy’ mains that can have a very great

detrimental effect on AC motors and therefore the turntable performance and

ultimately the sound.

And a quartz precision DSP then produces a perfect sine wave at 24VAC to run

the motor, resulting in a perfectly steady and constant platter rotation.

The AlphaDIG control is the perfect design solution. This engine system is

absolute stable in his rotation speed and in combination with the digital

control easy to use and reliable. The motor of the Thunder is on the left

back side of the turntable close to the Chassis.

As he has no contact with the Chassis there can´t be any vibration

transferred to the turntable. The NOVUM is equipped with 3 motors. They

drive a sub platter which is placed below the 24 Silencer platter. So the

complete drive system is not visible during normal operation.

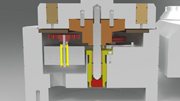

The Bearing

The bearing is the heart of every turntable. Through fundamental research

and development, we have invented a bearing with the ideal performance

characteristics of exact fit, extremely low noise, very low friction and

long term stability. The platter bearing component is manufactured from

special hardened and polished steel, with an extremely hard tungsten carbide

ball at its base.

The bearing housing uses perfectly matched and ‘aged’ sinter bronze inserts

which are self-lubricating; and therefore maintenance free. At the base of

the bearing, we use our specially developed ‘high-tech’ material TIDORFOLON.

Our bearing runs dry - without oil.. Here we have ultra-tight tolerances and

our Tidorfolon bearing is lifetime maintenance free. We trust in this

Bearing so it´s covered with a 10 year product warranty.

Technical data

| Construction

details |

Aluminum, brass Sandwich |

| Speed change |

33 and

45 rpm, 78 as option |

| Motor drive |

3

Synchronic motor, electronically regulated, Power-decoupled,

adjustable motor drive DSP controller |

| Bearing |

TIDORFOLON Bearing |

| Platter |

High precision plate made of aluminum, 5 cm thick, 15 kg with 24

Silencer modules double isolated. |

| Weight |

Turntable 143 kg

Stand 168 kg

311 kg total |

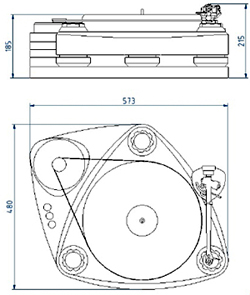

| Dimensions (W/D/H

in mm) |

480 mm depth, 670

mm width

ca. 36 kg depending on extras odered |

| Color |

Aluminum |

|

Manufacturers guarantee

|

10 Years |

HiFi News UK: Beautifully designed and

exquisitely engineered, this no compromise deck is simple to use and should

provide a lifetime of hassle-free performance. If you’re in the market for a

top-class vinyl spinner that requires minimum fettling then the Thunder

could be the answer. It’s massy built and state of the art electronics

combine to give a sound that’s expansive, rich with detail and effortlessly

involving.

|

|

Thunder is the first turntable we have manufactured with our new

revolutionary ‘Silencer Platter 3’ design, one of the most significant

improvements in our turntable designs. The Thunder is designed and built for

exceptional music reproduction, outperforming turntables costing much more.

A 70mm solid aluminium chassis forms the base of the turntable, on which up

to three arm attachments can be fitted for either 9” or 12” tone-arms of any

make. The 50mm thick platter is driven by its remotely sited motor and

AlphaDIG electronic control offers a perfect supply to the motor. The

turntable base has been designed for optimum stability; the large footprint

of the table generates more stability, to increase the weight concentration

at the base of the turntable. The Thunder is engineered to provide

exceptional sound, but its form is also attractively contemporary.

•A 50mm solid turntable platter made of aluminum with Silencer inserts. The

platter is made of a very soft alloy to optimize its periodic resonance, and

is coated on the rear side with resonance-reducing material. For the

Silencer- Platter3 the development target was clearly defined: Elimination

of vibration due to impacting airborne sound. Elimination of bearing noise,

increase of the gyrating mass. Serious elimination of all frequencies,

especially in the range 400-6000Hz. This was achieved by drilling 24 holes

into the turntable. The manufacturing process for the precision of these

holes was once more refined. The holes are drilled and afterwards separately

“line-bored”. This allows a clearance of less than 1/100mm. Perfect

conditions for the force-fitting of the 24 silencer modules. The “silencers"

are now an integral part of the turntable - but highly absorbing. Existing

vibration energy is quickly reduced and the Platter is immediately steadied.

To avoid unbalances through the additional holes these are manufactured in

the same setting as the outer contour. In this way the holes are absolutely

true to the centre of the turntable. As you can see, we have done everything

to develop a potentially perfect product.

•The bearing is the heart of every turntable. Through fundamental research

and development, we have invented a bearing with the ideal performance

characteristics of exact fit, extremely low noise, very low friction and

long term stability. The platter bearing component is manufactured from

special hardened and polished steel, with an extremely hard tungsten carbide

ball at its base. The bearing housing uses perfectly matched and ‘aged’

sinter bronze inserts which are self-lubricating; and therefore maintenance

free. At the base of the bearing, we use our specially developed ‘high-tech’

material TIDORFOLON. Our bearing runs dry - without oil.

•The external drive motor of the turntable is run by its own electronic

controller, called the AlphaDIG. It is a brand new design where fully

digital output stages and a quartz locked technology is used. It is

impervious to the negative effects of mains voltage fluctuations and

household appliances that produce ‘noisy’ mains that can have a very great

detrimental effect on AC motors and therefore the turntable performance and

ultimately the sound. And a quartz precision DSP then produces a perfect

sine wave at 24VAC to run the motor, resulting in a perfectly steady and

constant platter rotation. The AlphaDIG control is the perfect design

solution.

•The tone arm mounting plates are adjustable. The mounting of any desired

tone arm is possible, with a maximum of 3 tone arm mounting plates on one

turntable. • Three adjustable feet for simple macro and micro adjustments to

level the turntable.

• The high mass platter (with its inertia) is an integral part of the

turntable concept. Very low bearing friction, perfect motor drive control

and large platter inertia guarantee perfect synchronization and the best

sound. Highest precision manufacturing in Germany guarantees reliability of

this turntable. To make sure that every Thunder is exactly the same we

produce nearly every part on high precision computer controlled machines.

| Drive unit: |

Synchron motor, electronically regulated, Power-decoupled,

adjustable |

| Bearing: |

Highly precise roller burnished Tidorfolon bearing

|

| Chassis: |

Resonance-optimised

mass chassis with 3 adjustable feet, very soft alloy for low

resonance |

| Platter: |

High precision plate made of aluminium, 5 cm thick,15 kg

with 24 Silencer modules double isolated |

| Speed Range: |

33 1/3 RPM, 45 RPM |

| Power Suply: |

100 to 260V AC |

| Dimensions: |

440 mm depth,

440 mm width ca. 41-46 kg depending on extras odered |

Michael Fremer of Stereophile:June 2013

HiFi Wolrd review UK: This is a highly capable deck, which sits at the price

point comfortably…it is sonically pleasing.

There seems to be very little that is stormy about it, maybe it should have

been called “The sunshine” instead. It´s excellent value for the money and I

personally would be happy to live with its innate musical abilities, and

mellow sound. Speed stability measured a very low 0.043%. Extremely low

values making the turntable very speed stable. Excellent 5 Stars

|

|

The new STORM Mk2 turntable weighs in at 28kg and provides all the

advantages that true high mass turntables can deliver. STORM Mk2 offers rock

solid and tuneful bass, a stable and focused midrange, clear and detailed

high frequency reproduction – producing a sound-stage that has both natural

delicate musicality and great authority. The new STORM Mk2 design replaces

one of our best selling turntables, improving on the design with wider feet

spacing offering greater stability; improved platter resonance damping and

heavier platter; quality design to improve sound quality, not for its own

sake - something Acoustic Signature is known for worldwide. Of course, STORM

MK2 also has very low mechanical noise courtesy of our unique Tidorfolon

bearing design, and an externally sited motor, run by our BetaDIG

regenerative power supply ensure perfect rotation of the new platter. We

think it looks pretty cool as well!

•A 50mm solid turntable platter made of aluminium, a very soft alloy to

optimize its periodic resonance. There are 8 Silencer inserts fitted in the

platter, to further reduce resonance and the bottom face is coated with

resonance-reducing material.

•The bearing is the heart of every turntable. Through fundamental research

and development, we have invented a bearing with the ideal performance

characteristics of exact fit, extremely low noise, very low friction and

long term stability. The platter bearing component is manufactured from

special hardened and polished steel, with an extremely hard tungsten carbide

ball at its base. The bearing housing uses perfectly matched and ‘aged’

sinter bronze inserts which are self-lubricating; and therefore maintenance

free. At the base of the bearing, we use our specially developed ‘high-tech’

material TIDORFOLON. Our bearing runs dry - without oil.

•The external drive motor of the turntable is run by its own electronic

controller, called the Beta DIG. The AC mains voltage is converted to DC

current and a integrated Controller generates the necessary sine wave for

the motor fully digital. The frequency is Quartz looked and because of the

digital design not heat is created. Frequency stability and power are

increased to the former analog Version.The Beta DIG is impervious to the

negative effects of mains voltage fluctuations and household appliances that

produce ‘noisy’ mains that can have a very great detrimental effect on AC

motors and therefore the turntable performance and ultimately the sound. The

Beta DIG control is the perfect design solution.

Facts:

•A 45mm solid aluminium chassis forms the base of the turntable, on which

all arm attachments are fitted.

• The tone arm mounting plates are adjustable. The mounting of any desired

tone arm is possible, with a maximum of 3 tone arm mounting plates for

either 9” or 12” on one turntable. • The three widely spaced adjustable feet

offer simple macro and micro adjustments to level the turntable. The high

mass platter (with its inertia) is an integral part of the turntable

concept. Very low bearing friction, perfect motor drive control and large

platter inertia guarantee perfect synchronization and the best sound.

Highest precision manufacturing in Germany guarantees reliability of this

turntable. To make sure that every STORM Mk2 is exactly the same we produce

nearly every part on high precision computer controlled machines.

| Drive unit: |

Synchron motor, electronically regulated, Power-decoupled,

adjustable |

| Bearing: |

Highly precise roller burnished Tidorfolon bearing |

| Chassis: |

Resonance-optimised

45mm mass chassis with 3 adjustable feet, very soft alloy for low

resonance |

| Platter: |

High precision

machined 12 kg alloy platter 50mm thick incorporating 8 Silencers.

Resonance absorbing coating to bottom face |

| Speed Range: |

Synchronous

motor, electronically regulated, Power-decoupled through a S-Alpha

supply, switch for speed adjustment |

| Power Supply: |

230 or 115 V depending of your country, Alpha-S motor electronic

|

| Dimensions |

440 mm depth, 440 mm width

ca. 31-35 kg depending on extras ordered |

We at Acoustic Signature built excellent turntables real mechanical

masterpieces. But still they are record player for every day. How does that

work? we see good design, excellent sound and usability not as opposites but

as parts of a harmonious whole. Triple X .

With the Triple X we offer a wide variety of surface

option. 4 colors for the top plate and 2 for the plinth. Combined with 3

different platter otions. So there is a Triple X for everybody. For every

taste and requirement not anything - but just right.

9 inch, 10 inch and 12 inch tonearms? - no problem

Low vibration precise motor? - positioned in the left back side

Accurate quartz digital motor electronic ? built-in at no extra charge

Sandwich construction made of steel, MDF and damping components - Built-at

50 kg total weight!

100% Made in Germany

| Antrieb: |

1 Synchronmotor,

elektronisch geregelt, netzentkoppelt, einstellbar, Beta DIG

Motorelektronik |

| Lager: |

Hochpräzises

rolliertes TIDORFOLON Lager in Einzelanfertigung |

| Chassis: |

Sandwich

Massechassis mit 3 höhenverstellbaren Füßen. Sandwich aus Stahl, MDF

und Dämpfungsmaterial |

| Teller: |

Hochpräzisionsteller aus Aluminium, 5 cm stark, Silencer optional |

| Drehzahlbereich: |

33 1/3 UPM, 45

UPM mit Regelelektronik |

| Stromversorgung: |

96-260V AC |

| Maße: |

ca. 49-51 kg je

nach Ausstattung |

The Challenger turntable weighs in at 23kg, to

offer you our statement entry level high mass turntable. With this

Challenger design, we bring together one of the most sophisticated external

drive and power supply drive

systems,

with a massive high mass 50mm thick platter, supported by a solid 40mm thick

chassis. The Challenger is incredibly simple to set up, very versatile and

sonically its performance is outstanding, making many other brand turntables

costing up to three times the price sound poor in comparison. The Challenger

design offers a remarkable and consistent performance at a highly

competitive price, and has real visual appeal. systems,

with a massive high mass 50mm thick platter, supported by a solid 40mm thick

chassis. The Challenger is incredibly simple to set up, very versatile and

sonically its performance is outstanding, making many other brand turntables

costing up to three times the price sound poor in comparison. The Challenger

design offers a remarkable and consistent performance at a highly

competitive price, and has real visual appeal.

•A 50mm solid turntable platter made of aluminum. The platter is made of a

very soft alloy to optimize its periodic resonance, and is coated on the

rear side with resonance-reducing material. • The bearing is the heart of

every turntable. Through fundamental research and development, we have

invented a bearing with the ideal performance characteristics of exact fit,

extremely low noise, very low friction and long term stability.

•The bearing is the heart of every turntable. Through fundamental research

and development, we have invented a bearing with the ideal performance

characteristics of exact fit, extremely low noise, very low friction and

long term stability. The platter bearing component is manufactured from

special hardened and polished steel, with an extremely hard tungsten carbide

ball at its base. The bearing housing uses perfectly matched and ‘aged’

sinter bronze inserts which are self-lubricating; and therefore maintenance

free. At the base of the bearing, we use our specially developed ‘high-tech’

material TIDORFOLON. Our bearing runs dry - without oil.

•The external drive motor of the turntable is run by its own electronic

controller, called the BetaDIG. Like his big brother the AlphaDIG it

converts the AC mains voltage to DC current and a precision Microprocessor

then produces a perfect sine wave at 12VAC to run the motor, resulting in a

perfectly steady and constant platter rotation. The BetaDIG is impervious to

the negative effects of mains voltage fluctuations and household appliances

that produce ‘noisy’ mains that can have a very great detrimental effect on

AC motors and therefore the turntable performance and ultimately the sound.

The BetaDIG control is the perfect design solution and can supply up to 3

motors.

•The tone arm mounting plates are adjustable. The mounting of any desired

tone arm is possible, with a maximum of 3 tone arm mounting plates on one

turntable

• Three adjustable feet for simple macro and micro adjustments to level the

turntable.

• The high mass platter (with its inertia) is an integral part of the

turntable concept. Very low bearing friction, perfect motor drive control

and large platter inertia guarantee perfect synchronization and the best

sound. Highest precision manufacturing in Germany guarantees reliability of

this turntable. To make sure that every Calypso is exactly the same we

produce nearly every part on high precision computer controlled machines.

Reviews

STEREOPLAY-Germany

At the first view the Acoustic-Signature Challenger you think about "ultra

solid". This stands also for the sound not only the look. He offers a

ultradeep fundament and it is clearly focused. His extraordinary sound, the

excellent craftmansship make it an real Stereoplay Highlight

HiFi World Great Britain

"...with the kind of impact you usually associated with 6000EUR US

superdecks

not 2500 EUR designs. ...as this deck had the best timing of the group,

propelling the music along with incredible energy and drive.

It proved fast, with excellent resolving capabilities, had outstanding

transient attack and a huge dynamic range. This was tempered with superb

control, sonically it offered virtuallyno overhang, and could go from a

subtle wisher to room shaking volume and back again with ease.

The Challenger is is set to make a lot of people reconsider their

expectations of a deck at this price point and offer simply phenomenal value

for the money".

| Drive: |

unit 1

Synchronius motor, electronically regulated fully mains decoupled

adjustable, BetaDIG Motor electronic, external power supply

|

| Bearing: |

high precision

TIDORFOLON Bearing rollerbushed and paired with axle |

| Chassis: |

vibration

damped Chassis, 3 height adjustable feets, soft alloy for low

resonance. MANFRED |

| Platter: |

high precison

platter made of aluminium, 5cm height. 9kg weight |

| Speed Range: |

33 1/3 RPM, 45

UPM with motor electronic |

| Power Supply: |

230 Volt or

115V |

| Dimension: |

440b x 180h x

350d mm, 21-25Kg weight-depending on extras |

The Manfred Mk2 turntable is manufactured

using a choice of sumptuous real wood veneers, something you would expect on

a high end speaker system rather than an entry level turntable, or painted

high gloss piano black or white. The solid wooden plinth carries the

substantial high mass turntable platter bearing housing and tone arm

mounting plate. The turntable motor unit is remotely sited, close to the

plinth, and is the same motor as is used in our high end turntables, powered

from our S-Alpha regenerative power supply unit.

•The turntable platter is solid machined aluminium, 34mm thick and weighing

6kg. The platter is made of a very soft alloy to optimize its periodic

resonance, and is coated on the rear side with resonance-reducing material.

Existing vibration energy is quickly reduced and the Platter is immediately

steadied. The design is optimised to ensure both air borne and operating

vibration energy is damped and, to present the best operating conditions for

your arm and cartridge and offer you the best sound from your vinyl

collection.

•The platter bearing is the heart of every turntable and Acoustic Signature

have invented a bearing with the ideal performance characteristics of exact

fit, extremely low noise, very low friction and long term stability. The

platter bearing component is manufactured from special hardened and polished

steel. The bearing housing uses perfectly matched sinter bronze inserts

which are self-lubricating; and therefore maintenance free. At the base of

the bearing, we use our specially developed ‘high-tech’ material TIDORFOLON.

All bearings in Acoustic Signature turntables are designed to run dry -

without oil.

•The remotely sited drive motor sits neatly within a special aperture in the

Manfred Mk2 plinth, an elegant and practical solution to ensure vibration

isolation in the plinth is minimised. The sophisticated electronic control

is provided by the ‘S’ Alpha electronic motor controller, a single motor

controller, similar to its ‘big brother’ Alpha controller, as used with more

expensive Acoustic Signature turntables. It converts the incoming AC mains

voltage to DC current and a precision oscillator then produces a perfect

sine wave at 12VAC to run the motor, resulting in a perfectly steady and

constant platter rotation. The motor power supply is impervious to the

negative effects of mains voltage fluctuations and household appliances that

produce ‘noisy’ mains that can have a very great detrimental effect on AC

motors and therefore the turntable performance and ultimately the sound.

•The Manfred Mk2 turntable can be specified and delivered with any

production Rega tone arm, like the RB 251 or RB 301; or supplied with a tone

arm mounting plate to suit any other 9 inch arm. These arm plates are

exchangeable if you decide to change your arm. The plinth has three

adjustable feet for simple macro and micro adjustments to level the

turntable. The Manfred MK2 is available in real wood maple and cherry, or

piano black or white high gloss paint finishes to special order. The Manfred

Mk2 uses design concepts incorporated throughout the Acoustic Signature

turntable range: such as a high mass platter design, very low bearing noise

and friction, perfect motor drive control, and highest precision German

design and engineering. This guarantees long term reliability and high

performance; it ensures that every Manfred MK2 is exactly the same, as we

produce nearly every part on our precision computer controlled machines.

The Manfred MK2 is available in maple, cherry or piano black or white.

And why is this turntable is named Manfred?

Acoustic Signature are honouring Manfred Frohnhöfer the owners Father, who

sadly died in February 2007. He was an inspiration and always helped the

company in every way, was always helpful in finding solutions to develop and

build the company and the products, and will never be forgotten.

| Drive: |

unit 1 Synchronius motor, electronically

regulated fully mains decoupled adjustable,small Alpha Motor

electronic, external power supply |

| Bearing: |

high precision TIDORFOLON Bearing

rollerbushed and paired with axle |

| Chassis: |

real wood verneer 38mm Chassis, 3 height

adjustable feets, external motor |

| Platter: |

high precison platter made of aluminium,

34mm height. 6kg weight |

| Speed: |

Range 33 1/3 RPM, 45 UPM with motor

electronic |

| Power Supply: |

230 Volt or 115V |

| Dimension: |

430b x 170h x 340d mm, 16kg |

The Barzetti turntable; combines the precision

of high mass turntable designs with fresh and attractive contemporary looks.

4 Star review in What-HiFi UK:

4 Star review in What-HiFi UK:

Barzetti deck can challenge the very best. Once properly sited the Acoustic

Signature works very well. It´s a confident-sounding player with a stable,

large-scale output. Detail levels are good, and the ability to stay composed

with music which is varied and compley is impressive. The Barzetti has wide

dynamic limits and the ability to deliver an expansive, well focused

soundstage. Take built finish and ease of use into account and it´s hard not

to be impressed by this turntable

|

|

A stylish statement, with soft curved faces and

corners, making this highly engineered turntable a thing of true beauty and

built for high quality music reproduction – offering a very high level of

performance for a turntable in its price range. Using a newly designed 36mm

thick (6Kg) solid turntable platter made of aluminium. Machined with a

diamond cutting tool ensures the finish is beautiful and the platter

exceptionally well balanced for optimum performance. The bearing is the

heart of every turntable. Through fundamental research and development,

Acoustic Signature have invented a bearing with the ideal performance

characteristics of exact fit, extremely low noise, very low friction and

long term stability. The platter bearing component is manufactured from

special hardened and polished steel. The bearing housing uses perfectly

matched sinter bronze inserts which are self-lubricating; and therefore

maintenance free. At the base of the bearing, we use our specially developed

‘high-tech’ material TIDORFOLON, using our new TIDORFOLON 2 bearing design,

specially optimised for the Barzetti platter. All bearings in Acoustic

Signature turntables are designed to run dry - without oil.

The drive motor and its sophisticated electronic control are housed within

the turntable chassis. The ‘S’ Alpha electronic motor controller, developed

for the Barzetti from its ‘big brother’ Alpha controller, as used with more

expensive Acoustic Signature turntables. It converts the incoming AC mains

voltage to DC current and a precision oscillator then produces a perfect

sine wave at 12VAC to run the motor, resulting in a perfectly steady and

constant platter rotation. The motor power supply is impervious to the

negative effects of mains voltage fluctuations and household appliances that

produce ‘noisy’ mains that can have a very great detrimental effect on AC

motors and therefore the turntable performance and ultimately the sound. The

substantial one piece 50mm thick CNC milled MDF chassis forms the

attractively designed base unit of this turntable, within which the motor

and motor electronics are housed, along with the lower bearing housing and

tone arm mount. The tone arm mounting design allows simple infinite height

adjustment, making perfect horizontal arm align-ment possible for the Rega

arm supplied, doing away with the usual Rega arm spacers. There are

alternative arm base plates available for all 9” tone arms. Three adjustable

feet enable simple macro and micro adjustments to perfectly level the

turntable.

The chassis is finished with a 10-layered high gloss piano lacquer – the

highest quality paint finish on the market with a perfect mirror-like

surface in black or white.

The Barzetti has evolved out of and uses design concepts incorporated

throughout the Acoustic Signature turntable range: High mass platter design,

very low bearing noise and friction, perfect motor drive control, and

highest precision German design and engineering. This guarantees long term

reliability and high performance from a fully integrated and easy to use

turntable. Our newest stroke of genius!

| DRIVE-System: |

1 Synchronmotor,

elektronic controlled |

| Bearing: |

High Precision

TIDORFOLON Bearing II |

| Chassis: |

50mm Chassis ,

height adjustable feets |

| Platter: |

Aluminium

platter 35mm 6kg |

| Speed-Range: |

33 1/3 UPM, 45

UPM switchable |

| Voltage: |

230 Volt or 110

V |

| Dimensions: |

340 mm depth,

430 mm width Weight is 14kg depending on extras |

Any Question?

If you have any questions feel free to ask

Design - Wow!

Sound - Wow!

Production Quality - Wow!

Made in Germany - Wow!

Price - Wow!

WOW our newest turntable to the family of our German

precision-engineered turntables. Music really does matter for us also at our

entry level handcrafted vinyl-spinner made in Germany. The same proprietary

‘Tidorfolon’ Bearing design as used in all Acoustic Signature turntables, a

with10-year warranty. Stunning Design with touch sensor operation so no

button is on the clear designed surface. Brandnew fully digital motor

Electronic witha 20Mhz Micro Processor results in perfect speed stability.

4.5kg heavy duty Aluminium platter. Tonarm included.

Finish, black high gloss plinth, Acrylic Black or White Top Cover

WOW….Less than $2000 with Rega 202 tone arm.

| Antrieb: |

1 Synchronmotor, elektronisch geregelt,

netzentkoppelt, einstellbar, smallALPHA Netzteil |

| Bearing: |

High Precision Tidorfolon II Bearing |

| Chassis: |

24mm Plinth, Black high Gloss, Top Cover

available in white or black Acrylic |

| Platter: |

Aluminium Platter 24mm, 4.3kg weight

|

| Speed Range: |

33 1/3 UPM, 45 UPM with BetaDIG Motor

Electronic |

| Power supply: |

115V or 230 Volt |

| Dimensions: |

340x430x119mm DxWxH |

Any Question?

If you have any questions feel free to ask. By email, Fax or phone

15 years of experience in designing turntables

- Made in Germany

since 15 years Acoustic Signature is developing and producing turntables and

sell them to music lovers all over the world.

Special to this Anniversary we decisded to develop a entry level turntable

to make it easier to own a turntable of Acoustic Signature.

Exclusivity does not depend on the price!

The ECCO! turntable is manufactured using a soft grinded paint finish,

something you would expect on a high end speaker system rather than an entry

level turntable. The solid wooden MDF plinth carries the substantial high

mass turntable platter bearing housing and tone arm mounting plate. The

turntable motor unit is remotely sited, close to the plinth, and is the same

motor as is used in our high end turntables, powered from our S-Alpha

regenerative power supply unit.

•The turntable platter is solid machined aluminium, 24mm thick and weighing

4.3kg. The platter is made of a very soft alloy to optimize its periodic

resonance, and is coated on the rear side with resonance-reducing material.

Existing vibration energy is quickly reduced and the Platter is immediately

steadied. The design is optimised to ensure both air borne and operating

vibration energy is damped and, to present the best operating conditions for

your arm and cartridge and offer you the best sound from your vinyl

collection.

•The platter bearing is the heart of every turntable and Acoustic Signature

have invented a bearing with the ideal performance characteristics of exact

fit, extremely low noise, very low friction and long term stability. The

platter bearing component is manufactured from special hardened and polished

steel. The bearing housing uses perfectly matched sinter bronze inserts

which are self-lubricating; and therefore maintenance free. At the base of

the bearing, we use our specially developed ‘high-tech’ material TIDORFOLON.

All bearings in Acoustic Signature turntables are designed to run dry -

without oil.

•The ECCO! turntable can be specified and delivered with any production Rega

tone arm, like the RB 251 or RB 301; or supplied with a tone arm mounting

plate to suit any other 9 inch arm. These arm plates are exchangeable if you

decide to change your arm. The plinth has three adjustable feet for simple

macro and micro adjustments to level the turntable. The Manfred MK2 is

available in real wood maple and cherry, or piano black or white high gloss

paint finishes to special order. The Manfred Mk2 uses design concepts

incorporated throughout the Acoustic Signature turntable range: such as a

high mass platter design, very low bearing noise and friction, perfect motor

drive control, and highest precision German design and engineering. This

guarantees long term reliability and high performance; it ensures that every

Manfred MK2 is exactly the same, as we produce nearly every part on our

precision computer controlled machines.

| Antrieb: |

1 Synchronmotor,

elektronisch geregelt, netzentkoppelt, einstellbar, smallALPHA

Netzteil |

| Bearing: |

High Precision

Tidorfolon II Bearing |

| Chassis: |

38mm MDF wooden

plinth, 3 height adjustable feets, available in white or black matt

Finish |

| Platter: |

Aluminium

Platter 24mm, 4.3kg weight |

| Speed Range: |

33 1/3 UPM, 45

UPM with external Motor Electronic Alpha-S |

| Power supply: |

115V or 230

Volt |

| Dimensions: |

340x430x125mm

DxWxH , 10kg weight |

Any Question?

If you have any questions feel free to ask. By email, Fax or phone

|

systems,

with a massive high mass 50mm thick platter, supported by a solid 40mm thick

chassis. The Challenger is incredibly simple to set up, very versatile and

sonically its performance is outstanding, making many other brand turntables

costing up to three times the price sound poor in comparison. The Challenger

design offers a remarkable and consistent performance at a highly

competitive price, and has real visual appeal.

systems,

with a massive high mass 50mm thick platter, supported by a solid 40mm thick

chassis. The Challenger is incredibly simple to set up, very versatile and

sonically its performance is outstanding, making many other brand turntables

costing up to three times the price sound poor in comparison. The Challenger

design offers a remarkable and consistent performance at a highly

competitive price, and has real visual appeal.